Source of energy: Solar irradiance captured by rooftop PV modules sized for 5 kW installed capacity. The panels convert incoming solar photons directly into DC electricity through the photovoltaic effect. This source is intermittent, peaking around noon, which necessitates storage.

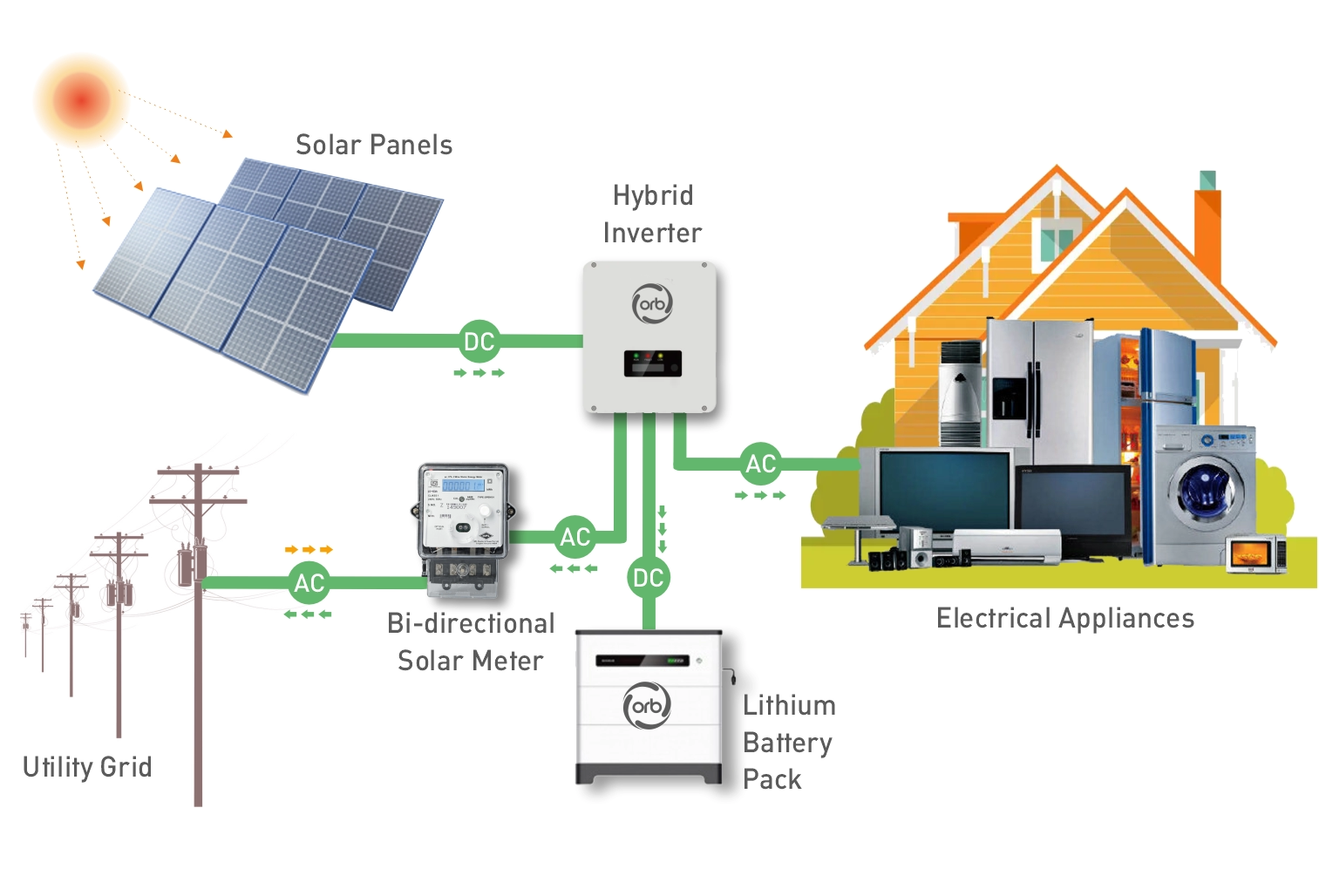

Conversion process: The raw DC power is first fed through an MPPT (Maximum Power Point Tracking) charge controller to optimize energy harvest regardless of cloud cover or temperature. The optimized DC is then converted into grid-compatible AC power by a hybrid inverter. A BMS (Battery Management System)-regulated lithium-ion battery bank stores any surplus energy, ensuring power availability for night-time operation and during grid outages.

Output / utilization: The system intelligently directs the AC output to three destinations: supplying immediate home loads (appliances, lighting), prioritizing battery charging, and finally exporting excess electricity to the utility grid under a net metering agreement. System protection is comprehensive, including rapid shutdown devices, fuses, surge protectors, and manual isolators for fire and electrical safety.

Real-world relevance: Rooftop PV dramatically lowers utility bills and reduces the homeowner's carbon footprint, promoting decentralized energy production. It creates local jobs in installation and maintenance. By integrating digital monitoring (IoT), the system achieves smart-grid compatibility, enabling predictive maintenance, fault detection, and real-time energy optimization across urban and suburban homes.